2 min read

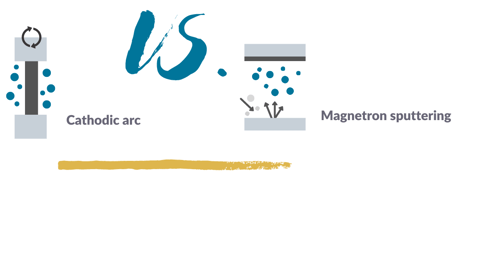

Coating companies: Service providers choose VaporTech systems to improve coating capabilities and meet the growing demand for PVD and DLC coatings. Compact solutions for medium to industrial-size applications: The VT-Series offers compact d...

Read More