Quick answers

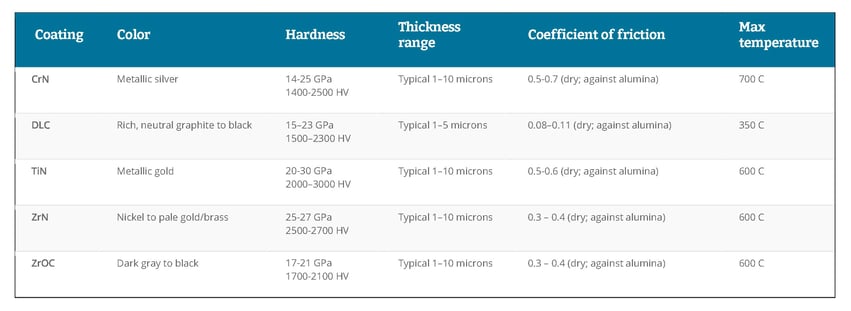

- Our top 5 PVD tribological coatings, Titanium Nitride (TiN), Diamond-Like Carbon (DLC), Chromium Nitride (CrN), Zirconium OxyCarbide (ZrOC), and Zirconium Nitride (ZrN), offer superior durability, wear resistance, and corrosion protection.

- These coatings enhance tool life, reduce friction, and improve product performance in industries such as medical, automotive, and manufacturing.

- VaporTech’s PVD coating systems allow businesses to apply high-performance coatings in-house, ensuring quality control and cost efficiency.

Performance coatings

Performance coatings change a part or product’s external/surface properties without affecting internal material characteristics. These coatings usually change the hardness and toughness of the part’s surface to improve durability and reduce friction and wear. Many types of functional coatings offer different properties for different applications. These finishes must be tested and optimized to successfully develop an ideal solution for your application. With so many options and individual companies’ collections of branded coating names, it’s easy to become overwhelmed. To simplify, we offer a brief overview of our top five performance coatings for the physical vapor deposition (PVD) process.

Our top 5 functional coatings countdown

5. The ‘general-purpose’ pro

Zirconium nitride (ZrN) is an exceptional general-purpose coating that is very hard and tough for good wear resistance, excellent corrosion resistance, and biocompatibility. Common uses for ZrN include punching and cutting tools, machining, and medical devices.

4. The good-looking durability champ

Zirconium OxyCarbide (ZrOC) is moderately hard and tough, offering wear resistance and excellent corrosion resistance. For these reasons, it’s commonly used to coat consumer products that must be wear-resistant. This coating has a visually pleasing graphite or black appearance and functional properties.

3. Sliding into third with multiple functions

Chromium nitride (CrN) has a lot to offer. It’s exceptionally hard and tough. It reduces friction, is resistant to sliding and impact wear, has excellent corrosion and oxidation resistance, and is a non-stick option for many other materials. CrN’s many properties make it ideal for dies and molds, pump parts, Cu/Al machining tooling, engine components, and as a replacement for functional plated hard chrome.

2. Diamonds are forever (or at least for a very long time)

Diamond-like carbon (DLC) is an amorphous carbon coating—a whole category of materials containing varying amounts of graphite and diamond. These combinations create high hardness, low friction, resistance to sliding wear, corrosion resistance, biocompatibility, and a striking, on-trend, dark-gray look. DLC is, therefore, suited to various uses, including automotive components, medical devices, dies, molds, firearms, cutting tools, sporting goods, and other durable consumer goods.

1. The ‘gold’ standard

Titanium nitride (TiN) coating is perhaps the most used and most well-known choice for physical vapor deposition (PVD). Combining a non-metallic element (Nitrogen) with a transition metal element (Titanium) forms a refractory material resistant to alteration. TiN provides both good mechanical properties and a lustrous gold color. It’s used in various applications, including medical devices and surgical tools, cutting/punching tools, rotating shank tools, molds/dies, and iron alloy machining.

Side-by-side functional coatings comparison

Hard vs. Tough

Although the public uses “hard” and “tough” interchangeably, the two have independent meanings in materials science. Hardness is the ability to withstand friction. Toughness is an item’s ability to resist breakage under force. Following are some real-world examples:

Although the public uses “hard” and “tough” interchangeably, the two have independent meanings in materials science. Hardness is the ability to withstand friction. Toughness is an item’s ability to resist breakage under force. Following are some real-world examples:

- A diamond is very hard. It’s extremely difficult to scratch. However, it’s not tough because you can shatter it with a hammer.

- Silly putty isn’t hard, but its ability to stretch and deform before breaking means it’s pretty tough!

- Bulletproof glass is both hard and tough.

Resources

Guide to Functional Coatings

The V.MAX1500 industrial products coating system [video]

About VaporTech

Vapor Technologies, Inc. (VaporTech®) manufactures PVD coating machines that produce functional and durable/decorative (color PVD) coatings. Our systems are right-sized with a range of options. All can create these top available coatings. Leading companies worldwide and medium and small operations use our machines to coat their products. For more information, email sales.

Please see our blog post about the new V.MAX1500 functional coatings machine.

View a recording of our Q&A on industrial coatings and the V.MAX1500 coater here.

How Our Labs Develop PVD Coatings for Customer Needs

Add Value to Your Products with Premium Decorative PVD Finishes

.png?width=2000&height=1167&name=Square%20social%20posts%20templates%20(11%20x%208.5%20in).png)