Color PVD Coatings: The Future Is Bright

Quick answers

- Color PVD coatings are created by adding elements that cause a reaction changing the color of the finish.

- Decorative thin-film coatings are durable and corrosion resistant, but don't have the same tribological attributes as thick films for wear applications.

- There are over 15 options for color PVD coatings to fit a variety of decorative needs.

How are PVD color coatings created, and what colors are available? Read on.

To create color PVD finishes, you deposit films with specific stoichiometries (ratios of certain elements). Typically, you take a base metal and react it with a reactive gas to form a very thin ceramic compound. For example, titanium coatings are usually silver or gray when deposited, but adding nitrogen to form a titanium nitride (TiN) compound produces a dazzling gold color. Furthermore, you can create specific rose gold shades. Add a small amount of carbon to TiN to form titanium carbonitride (TiCN).

Note that certain base metals can produce a wide range of PVD finishes and color coating combinations, ranging from gray to dark bronze to blue. In contrast, others are limited to only gray-toned colors. This difference is why most durable decorative coatings are zirconium-based. Another reason is that the compounds that create the most striking colors exhibit excellent wear- and chemical-resistant properties.

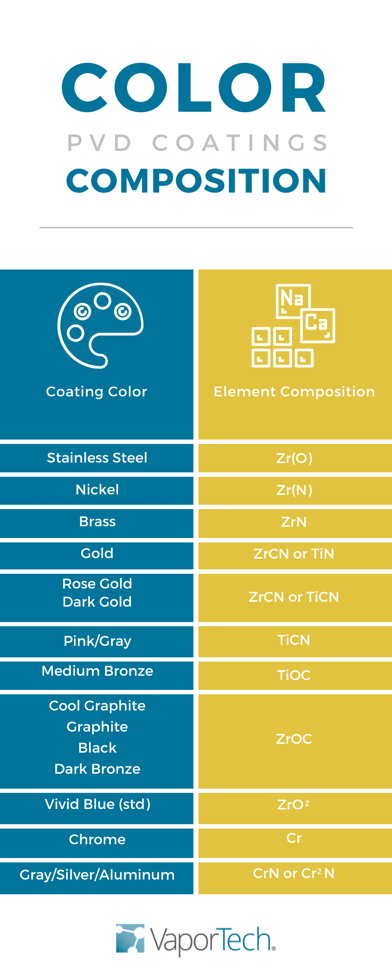

The table below displays different element combinations that create specific PVD coating colors.

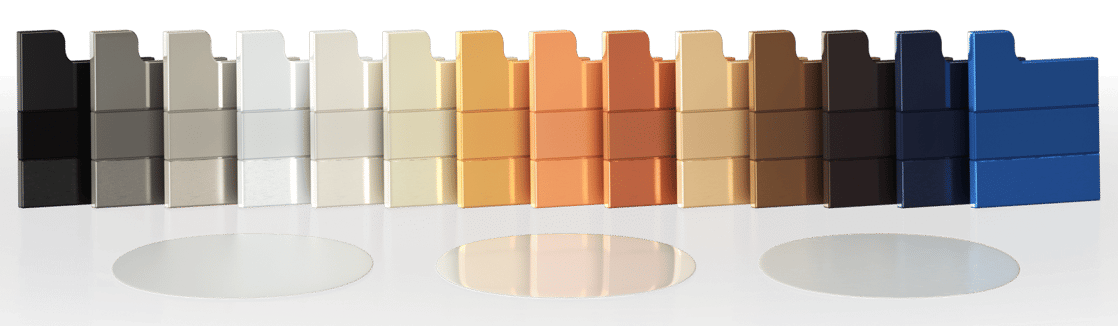

Users deposit various PVD coating colors on different textures with these durable color coatings. Since all color PVD finishes match the surface texture of your substrate, each distinct surface creates a specialized look and feel. Depositing on a glossy substrate makes the coating appear vibrant, while depositing on a textured substrate provides a more muted look.

Users deposit various PVD coating colors on different textures with these durable color coatings. Since all color PVD finishes match the surface texture of your substrate, each distinct surface creates a specialized look and feel. Depositing on a glossy substrate makes the coating appear vibrant, while depositing on a textured substrate provides a more muted look.

Some PVD coatings produce the same color regardless of film thickness (e.g., TiCN), while others are thickness-dependent (most oxides). To provide a uniform color throughout a 3-dimensional part, colors that require specific coating thicknesses (also known as interference films) may require specialized racking. Please contact us for more information about racking and color uniformity.

How long do durable color PVD coatings last?

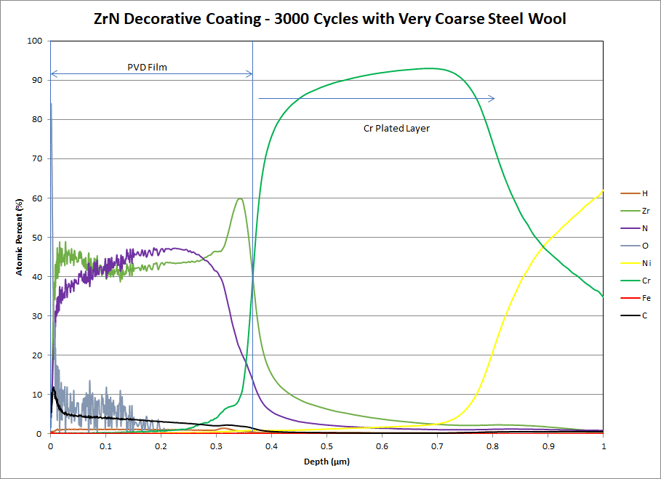

Decorative thin-film coatings are durable, providing excellent wear and corrosion resistance. However, they don’t have the same tribological attributes as the thicker films designed for wear applications. Since the primary coating function is to create cosmetic finishes, rather than tribological ones, the thickness of most decorative films is typically less than 0.5 µm.

Durable Color PVD Coatings

All our durable color PVD coatings can withstand abrasion against steel wool. The image on the left shows a ~0.4 – 0.5 µm-thick ZrN-coated panel subjected to our “steel wool scrub test” for 3000 cycles. This test involves attaching a 3.8 lbs. weight to a coarse steel wool pad that is cycled against the coated panel. As you can see, the steel wool did not damage the panel. Further chemical elemental analysis of the coating depth profile conducted with our Glow Optical Discharge Spectrometer (below) shows that most of the coating remains and may withstand many more cycles!

Are PVD color finishes a good fit for your application?

All VaporTech durable-decorative coatings are deposited using our LTAVD® (Low-Temperature Arc Vapor Deposition) cathodic arc technology. This process produces coatings that would be very difficult for other PVD technologies to create at much lower temperatures, while maintaining high deposition rates and excellent properties. Therefore, we can apply these coatings to various substrates (including plastic and zinc).

What coating color combinations can VaporTech create?

VaporTech offers a rainbow of standard colors and can optimize coatings to match the required decorative finish. Colors include:

|

|

PVD color coatings have excellent wear resistance while providing a high-value appearance. They suit many applications, from automotive trim and surgical tools to architectural products such as faucets or doorknobs, to blades and firearms. PVD colors are a great differentiator for industrial products, including cutting tools and molds & dies.

PVD Coating Durability: Does PVD Coating Wear Off?

PVD Colors: How to Ensure Beautiful, Consistent Colors

.png?width=339&height=170&name=Link%20to%20Signature%20collection%20blog%20(900%20x%20450%20px).png)