Compare PVD Coating Systems: Which One is Right for You?

Quick answers

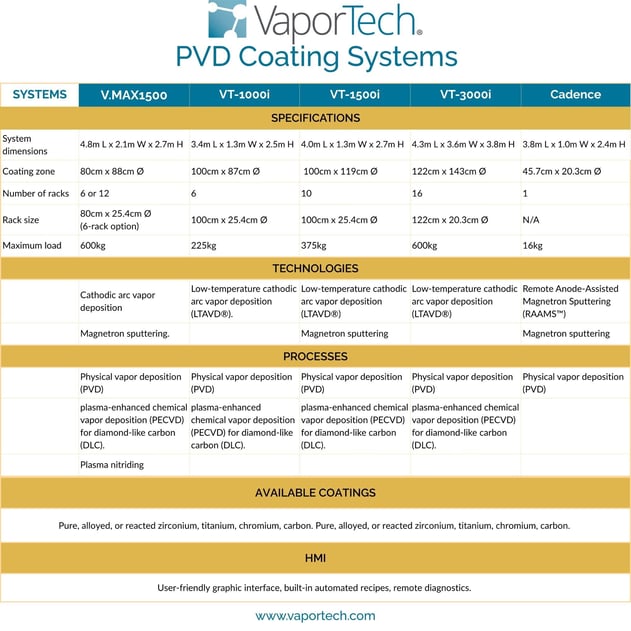

- VaporTech offers 5 compact vapor deposition systems that deposit both color PVD finishes and hard, high-wear industrial coatings.

- i-Series™ machines come in 3 sizes and configurations to meet your manufacturing operation’s needs and budget.

- The V.MAX1500™ system increases hardness, reduces friction, and enhances durability in high-wear applications.

- The Cadence® system deposits dense, smooth coatings similar to those produced by HIPIMS technology, but faster.

In-depth guide to choosing a PVD coating system

Whether you need a compact machine or a large-batch coating system, VaporTech has a solution for your PVD coating needs.

Our PVD coating machines deposit coatings that enhance your products’ look, feel, function, and durability—without affecting critical dimensions or performance. These aren’t simply metal layers but compound materials that can be customized to be harder than case-hardened steel or more scratch-resistant than hard chrome. Coatings range from silver and rich black to a wide range of beautiful colors. Running our systems costs less than $20 per batch.

How much space do I need to run a PVD system?

We offer a range of PVD & DLC/PECVD equipment designed for everything from high-volume, large-scale manufacturing to smaller operations. In fact, most of our systems are delivered on 1 pallet and would fit in a 2-car garage.

PVD coating equipment at a glance: technical specifications

VaporTech® PVD coating systems review

The V.MAX1500(™) system: designed for performance

The flexible, efficient, cost-effective V.MAX1500 batch coating system is ideal for industrial product manufacturers and service providers. Applications include cutting and forming tools, precision-engineered components, automotive/aerospace parts, medical devices, and other industrial products that benefit from lower friction, enhanced durability, and product longevity.

The V.MAX 1500 features:

- Up to 6 cathodic arc or magnetron sputtering sources that deposit binary, ternary, and quaternary metal-based and DLC coatings.

- Maximum throughput in a compact, easy-to-install system.

- A parts turntable that is easily removed for loading and maintenance.

- Duplex process for PVD and plasma nitriding.

i-Series™ systems: proven cathodic arc PVD coating

VaporTech VTi-Series PVD coating machines utilize a unique, centrally mounted coating source with parts that rotate around the perimeter of a large, actively cooled chamber. They come in three sizes for medium to the largest industrial operations.

i-Series features:

- Deposits both PVD and DLC coatings in the same chamber.

- Lower temperature cathodic arc process coats metal and plated plastic.

- Excellent color uniformity throughout the chamber.

- Simple maintenance and a low coating cost per batch.

- Optional single or dual rotary magnetron sputtering sources. *1500i only*

The VT-1000i™ system: Small but mighty

Our smallest VaporTech i-Series™ machine, the VT-1000i system, offers a compact 6-rack design coating parts up to 100cm (39.37 in) long. Perfect for limited manufacturing space, this system is ideal for manufacturers who previously considered vacuum coating systems too large, complicated, or expensive.

The VT-1500i™ system: A hybrid workhorse

The VT-1500i system, our mid-sized i-Series machine, has 67% more capacity with 10 racks vs. 6 on the VT-1000i system. Its compact footprint is perfect for limited manufacturing space. This unique system combines cathodic arc and optional magnetron sputtering technologies in a single machine, with up to 3 PVD sources. This system is ideal for larger manufacturing operations and coating service providers.

The VT-3000i™system: High capacity and throughput for the largest operations

The streamlined 3000i system features the largest i-Series chamber in a smaller footprint than other industrial coaters. It offers high throughput and accommodates larger parts, up to 122cm (48 in) long. It is ideal for large-scale operations and is used by leading manufacturing operations worldwide.

The Cadence® system: High-performance coatings for precision components

The Cadence system’s proprietary RAAMS™ (Remote Anode Assisted Magnetron Sputtering) technology enhances coating structure, hardness, and wear resistance. This product deposits dense, smooth coatings similar to those produced by HIPIMS, but at higher deposition rates. It’s ideal for industrial tooling, medical devices, and other precision components.

Read more blog posts.

Why Is Physical Vapor Deposition (PVD) Also Called ‘Vacuum Coating’ Or ‘Vacuum Deposition?’

What is PECVD? Use it to Create DLC coatings in Your Vapor Deposition System.

.png?width=339&height=170&name=Link%20to%20Signature%20collection%20blog%20(900%20x%20450%20px).png)