Functional DLC Variants Target Specific Properties for Distinct Applications

Quick answers

- For high contact pressure and sliding wear, ta-C coatings are extremely hard with a low coefficient of friction.

- a-C:H coatings are used for similar applications to ta-C that also require high wear-resistance properties.

- a-C:H:W coatings add tungsten for applications requiring toughness, thermal stability, and adhesion properties.

- VaporTech® machines, particularly the V.MAX1500™ industrial products coating system, excel at depositing functional DLC coatings.

What are DLC (diamond-like carbon) coatings?

The term DLC refers to carbon-based coatings that contain the bonding characteristics of the two naturally occurring (allotropic) forms of carbon: diamond and graphite. DLCs combine properties such as hardness and a low coefficient of friction, which satisfy the requirements for various mechanical applications.

Why do products need DLC coating variants?

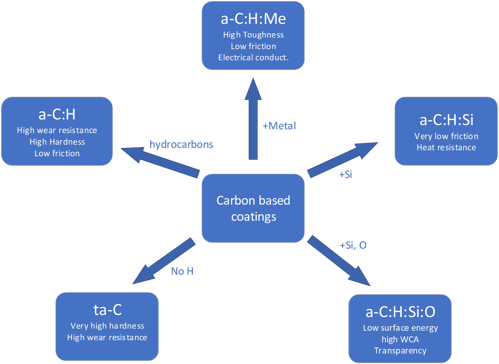

Differences in applications, such as the type of substrate, mechanical loading, environment (presence of a lubricant, air, vacuum), and counterpart material, led to the development of DLC performance “variants.” These variants include undoped hydrogenated amorphous carbon (a-C:H ) and hydrogen-free tetrahedral amorphous carbon (ta-C), as well as metal-doped (a-C:H:Me) and non-metal-doped (a-C:H:X) DLC coatings.

Physical vapor deposition (PVD) processes, such as filtered-arc deposition from a graphite target, typically produce hydrogen-free ta-C coatings. These coatings are extremely hard (>>30GPa) and have a low coefficient of friction (COF) ~ 0.1 – 0.2 against steel in air. They are usually used in applications with high contact pressure and sliding wear.

The plasma-enhanced chemical vapor deposition (PECVD) process creates undoped hydrogenated a-C:H coatings. A plasma dissociates a carbon-containing gas, and the coating forms when the substrate’s surface adsorbs the carbon-hydrogen species. These coatings’ hardness can vary from 15 to 25 GPa, which tends to be inversely proportional to the film’s hydrogen content. They also present a low COF, ~0.15-0.2 against steel in air, and are used similarly to ta-C.

Producing the targeted DLC coatings your product requires

We can modify the composition and properties of hydrogenated amorphous carbon coatings by adding small amounts of doping elements. Incorporating a metal (e.g., W, Ti, Cr, Nb) leads to the formation of metal carbides in a matrix of amorphous carbon (DLC). Sputtering of the metallic material in a carbon-containing atmosphere produces these coatings. a-C:H:Me finishes are not as hard as a-C:H and ta-C coatings and therefore tend to be less resistant to wear in dry conditions. However, they can exhibit lower internal stresses, improved adhesion, and greater toughness than undoped members of the DLC family. Amongst metals, tungsten (W) is the most commonly used commercially. a-C:H:W coatings are ideal for applications such as gears, ball bearings, and punches.

Adding light elements (e.g., Si, F, B, N, O) to DLC can also enhance some properties over undoped coatings. Among the elements mentioned, silicon is the most common addition to hydrogenated DLC coatings. Its deposition occurs by dissociation of carbon and silicon-containing sources via PECVD. Compared to non-doped DLC, a-C:H:Si typically has lower internal stress, improved adhesion, and superior thermal and chemical stability. As for a-C:H:Me, hardness and wear resistance are not as high as non-doped DLC coatings. However, a-C:H:Si coatings exhibit superior corrosion resistance, making them excel in applications that require good release properties.

Resources for functional PVD information:

- The VaporTech guide to functional PVD coatings (download)

- The V.MAX1500 industrial products coating system (video)

For more information about how our machines can deposit the right performance DLC coating for you, please call 303-652-8500 or email vtsales@vaportech.com

Your Top 3 DLC Coating Questions Answered

PVD & DLC Coating: One System, Multiple Coating Types [video]