2 min read

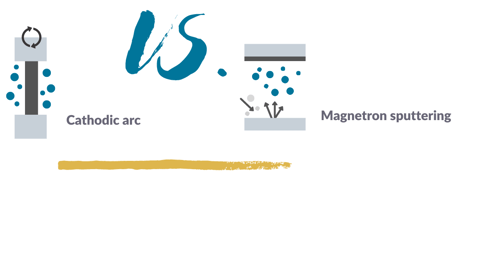

Quick answers PVD coatings add a durable protective layer to manufactured parts. PVD coatings add hardness, wear resistance, chemical resistance, and corrosion resistance properties to consumer and industrial products. PVD coatings increase...

Read More